| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | SEAMOUNT |

| Model Number : | OEM |

| Certification : | ISO, CE |

| Price : | USD 10-15/kg |

| Payment Terms : | T/T, Western Union |

| Supply Ability : | 50000KG per month |

| Delivery Time : | 5-30 work days |

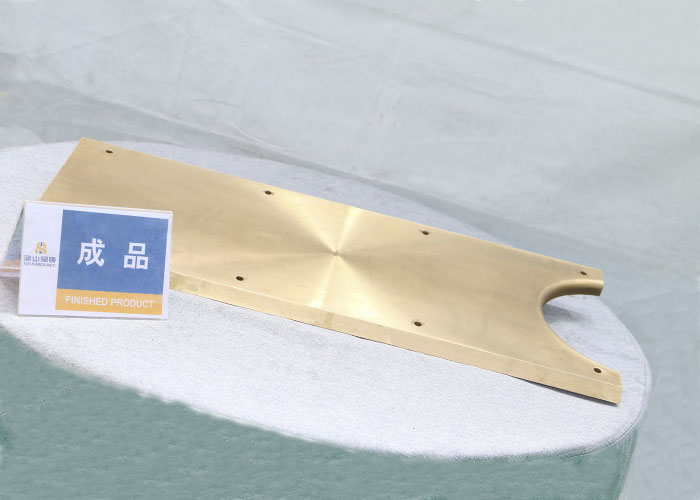

Customized High Density C86300 Manganese Bronze Machinery Parts Wear Plate

Product Details:

Wear plate: Wear plate (also called copper disc,bronze plate, friction disc, bronze friction disc, upper circular plate) is a very key part of the copper castings in cone crusher. Its role is: a, reduce the sliding friction of equipment in operation, reduce power loss; b, greatly increase the wear-resistant parts of cone crusher. Service life, reduce maintenance and maintenance costs, strive for higher equipment utilization rate; C. Effective protection of steel parts in contact with them from wear, when copper parts wear easily replaced. The wear plate is installed at the lower top of the main shaft of the cone crusher and above the middle friction disc. The pressure is very large, and his material and size requirements are relatively high. Especially the clearance between him and the middle friction disc is the most important technical difficulty. Because of the errors in manufacturing and installation, it is easy to cause malignant equipment accidents such as disk cracks or even comminuted fracture or excessive friction resistance in operation. The burning of tiles occurs in the equipment. Therefore, the key to the normal operation of the equipment is to select the upper disk with guaranteed material and processing size. The wear frequency of upper disk is higher.

| Company Type | Manufacture factory CE, ISO Audit supplier |

| Material | Brass, Tin bronze, Lead bronze, Aluminum bronze, ect |

| Standard | ISO, CE |

| Feature | 1. High load capacity ; 2. Low coefficients of friction ; 3. Good heat conductivity ; 4. High corrosion resistence ; 5. Long life and maintenance-free ; 6. No contaminant by oil or grease |

| Quality Assurance | 2D Projector , Height Gague, Micrometer , Roughness Tester, CCD Autimatic Testing Machine CCD, Calipers |

| Tolerance | Roundness:+/- 0.01mm Flatness:+/- 0.005mm Height and length: +/- 0.01mm |

| Process | Centrifugal casting,Sand casting,Machining,Injection |

Company information

Xinxiang Haishan Machinery Co., Ltd. is a comprehensive company specializing in mining, industry, iron and steel smelting industry, production, processing and sales of copper, aluminum base alloy parts and appliances for domestic use in Central China. At present, it is the largest casting, processing and business of copper and aluminum parts in Central China.

Packing&Shopping

Export packing in wooden case:

1. Plastic bags wrapped

2. Bubble paper / Pearl cotton wrapped

3. Durable wooden carton / box

4. Foam plate in the bottom

FAQ

2. Q: How to visit your factory?

A: Our company is located in Xinxiang Henan prov.China. welcome everyone from home and abroad to visit.

3. Q: Why should i choose you?

A:A Passion--- With a young and vibrant team can keen eye to focus

on your needs

B.Professional --- With advanced casting technology,sand casting /centrifugal casting /metel casting to meet different client's product requirpment

C.Patiently---- All the custom machined bushings can be produced by the drawings,sketchers, also we provide drawing design based on the request

4. Q: How do you control the quality?

A: We have a series of testing equipment such as Chemical

Composition Analyser,Hardness tester,DYE Penetration

Inspection,Ultrasonic Testing,

Also we support the quality test by the 3rd Party like SGS

5. Q:How long is the lifetime of these bushings?

A:Normaly 3-5 years according to the diffirent working

environment.With gentle care they can help your machine output

more,

6. Q: Can you give me a discount?

A:We believe quality equal the price. As we all know the larger

quantity orders, the more discount.

7. Q: How about your after-sale service and the problmes repsonse speed ?

A:We are responsible for every sold product.If there any problems please take pictures and count the quantities,will feedback solutions and PAR Preventive Action Report to you within 12 hours.

8. Q:What about the payment terms?

A:We'd like to hear customers' opinion, Normally payment terms as

below

A. 50% T/T in advance the balance before ship

B. 100% L/C at sight

C. Paypal (small purchase)

D. Ali Trade assurance payment on line by the credit card

|