| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | SEAMOUNT |

| Model Number : | OEM |

| Certification : | ISO, CE |

| Price : | Negotiable |

| Payment Terms : | T/T, Western Union |

| Supply Ability : | 50000KG per month |

| Delivery Time : | 5-30 work days |

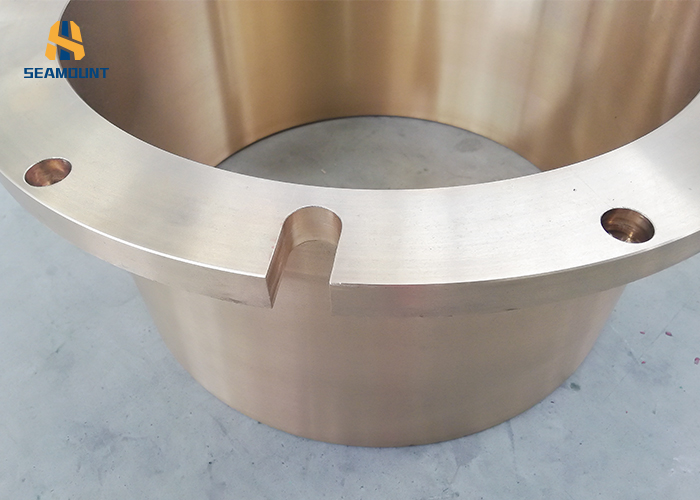

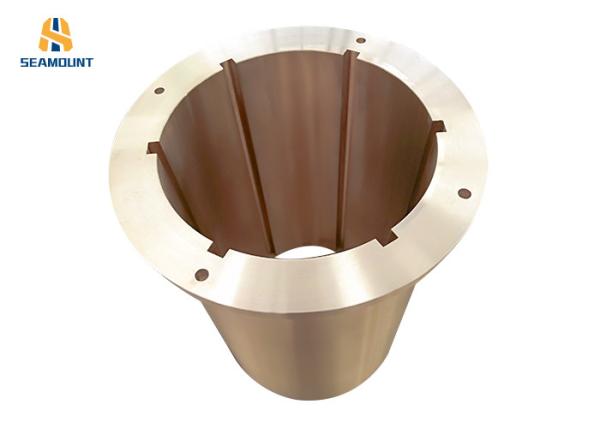

Centrifugal Casting Sintered Bronze Bush Good Heat Conductivity

Xinxiang Haishan Machinery Co., Ltd. is a professional non-ferrous metal casting factory and a famous copper sleeve manufacturer. Our factory has many years of experience in casting copper sleeve, and is a copper sleeve manufacturer gradually developed

Product details:

| Company Type | Manufacture factory SGS Audit supplier |

| Material | Brass, Tin bronze, Lead bronze,Aluminum bronze,ect |

| Standard | ISO 2008,SGS,CE |

| Fearture | 1. High load capacity Cood anti-wearing 2. Low coefficients of friction 4. High corrosion resistance 6.No contaminant by oil or grease |

| Process | Centrifugal casting,sand casting,Machining,Injection |

| Quality assurance | 2D Projector, Height Gague,Micrometer,Roughness Tester, CCD Autimatic Testing Machine CCD,Callipers |

| Tolerance | Roundness::+/- 0.01mm. Flatness:+/- 0.005mm. Height and length:+/- 0.01mm. |

| Lead time | According to required time |

| MOQ | 50KG |

Product description

Copper sleeve, also known as copper bearing, needs to be lubricated with oil. It is made of various copper alloys to lubricate the mechanical parts. It is an important component of the machinery with various large and heavy machinery. The bearing can bear radial force and axial force, but the copper sleeve can not be used at the same time. But the advantage of copper sleeve is that it can prevent sparks when parts collide,In some special places, copper sleeve is equivalent to the function of bearing, such as the place with heavy load, low speed and large impact of mechanical load.

Advanced production system ensures the stability and reliability of product quality, and perfect quality management system ensures the continuous development of brand.

The following are the precautions of bronze copper sleeve in casting process.

1: When casting the copper sleeve, each process must be handled carefully, for example, the core must be placed in the right position when closing the box, so as to avoid that the cast product cannot be processed according to the size due to this reason.

2: Before processing, first clean the casting, then get on the car, first calibrate, then get off the car when processing to the semi-finished product, and cool it, because copper has shrinkage, in order to process accurately, get on the car again when the workpiece is placed at room temperature for processing.

3: After the finished product, especially the straight sleeve cannot be placed horizontally, it shall be placed vertically to prevent deformation.

4: The packaging shall be reserved. The assembly surface and working surface of the copper sleeve shall not be exposed to the air. A layer of oil shall be applied and wrapped with newspaper or plastic cloth. If the oil fails or the copper surface is exposed to the air, the oil and packaging shall be replaced. Single vertical place, can not collide with each other, the bottom pad a little thick paper shell or clean rubber pad. The storage place shall be ventilated and dry.

|