| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | SEAMOUNT |

| Model Number : | OEM |

| Certification : | ISO, CE |

| Price : | Negotiable |

| Payment Terms : | T/T, Western Union |

| Supply Ability : | 50000KG per month |

| Delivery Time : | 5-30 work days |

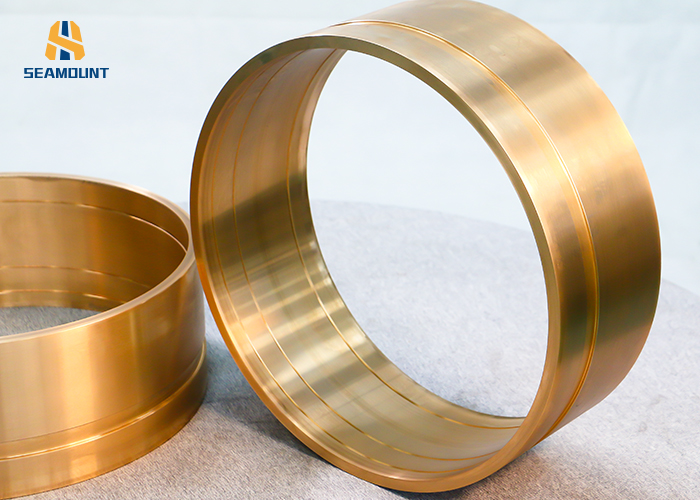

Sliding Bronze/Brass Copper Bushing Durable Large Impact Load Capacity

product feature

1. High load capacity Cood anti-wearing

2. Low coefficients of friction

3.Good heat conductivity

4. High corrosion resistance

5.Long life and maintenance-free

6.No contaminant by oil or grease

Product description

Bronze sleeve - the copper sleeve on the shaft plays the role of bearing, also known as sliding bearing. It is a bearing working under sliding friction. The relative shaft is rotating. Generally, it needs to be assisted by a lubrication system. The sliding bearing is stable, reliable and noiseless. Under the condition of liquid lubrication, the sliding surface is separated by lubricating oil without direct contact, and the friction loss and surface wear can be greatly reduced. The oil film also has certain vibration absorption capacity.

Problems to be noticed in processing of copper bushing:

As we all know, copper sleeve has high hardness and good wear resistance, which is not easy to produce the phenomenon of seizing, and it also has good casting performance and machinability. It has very strong corrosion resistance. So it is also very careful in the process of manufacturing, so what should we pay attention to in the process of manufacturing?

The first point: when casting the copper sleeve, each process must be carefully handled. For example, the core must be placed in the right position when the box is closed, so as to avoid that the cast product cannot be processed according to the size due to this reason.

The second point: before processing, first clean the casting, then get on the car, first correct, then get off the car when processing to the semi-finished product, and cool down. Because copper has shrinkage, in order to process accurately, get on the car again when the workpiece is placed at room temperature for processing.

Third point: after the finished product, especially the straight sleeve cannot be placed horizontally, it should be placed vertically to prevent deformation.

The fourth point: packaging, to retain the amount, to avoid accidental collision in the process of transportation and lead to deformation.

Product details:

| Company Type | Manufacture factory SGS Audit supplier |

| Material | Brass, Tin bronze, Lead bronze,Aluminum bronze,ect |

| Standard | ISO 2008,SGS,CE |

| Process | Centrifugal casting,sand casting,Machining,Injection |

| Quality assurance | 2D Projector, Height Gague,Micrometer,Roughness Tester, CCD Autimatic Testing Machine CCD,Callipers |

| Tolerance | Roundness::+/- 0.01mm. Flatness:+/- 0.005mm. Height and length:+/- 0.01mm. |

| Lead time | According to required time |

| MOQ | 50KG |

Our company specializes in the production of crusher copper parts, with many years of production, casting, processing experience, is a new professional manufacturer of customized cone broken copper sets in Henan Province, the products are exported to Germany, Russia, the United States, Bulgaria, Japan and all over China, deeply recognized by the majority of customers.

Production technology: sand casting, metal casting, centrifugal casting.

The casting diameter is 40mm-2000mm, the weight of single casting piece is 0.1-4000kg, and the centrifugal diameter is 1800mm.

|